<For high demand large-sized or medium-sized precision plastic mold and alloy parts.>

1.International Standard

| GB | DIN | ASIA | JIS |

| 3Cr2MnNi | 1.2311 | P20 | PDS-S |

2.Chemical Composition(Wt%) :

| 1.2311 | C | Si | Mn | Cr | Mo | S | P |

| 0.35-0.45 | 0.20-0.40 | 0.60-1.00 | 1.80-2.10 | 0.30-0.55 | ≤0.003 | ≤0.003 |

3.Available Size(mm) :

| Flat Bar Size | Round Bar Size(mm) | ||||

| Thickness | Width | Length | Diameter | Length | |

| 10-700 | 155-2200 | 2000-6000 | 20-200 | 2000-6000 | |

4.Product Process:

Electric-Furnace Smelting(EF)→Ladle Furnace(LF)→Vacuum Degassing(VD)→ Argon protected ingot →Multidirectional Forging → (Concave forging →)Normalizing+Hydrogen Diffusion Annealing → Ultrasonic Flaw Detection →Queching+Tempering Prehardened

5.Feature:

1. Material uniformity, excellent cutting, and polishing.

2. High toughness and high plasticity.

3. High wear resistance at high and low temperatures.

4.Excellent overall hardening.

5.Good high-temperature strength and heat resistance Fatigue.

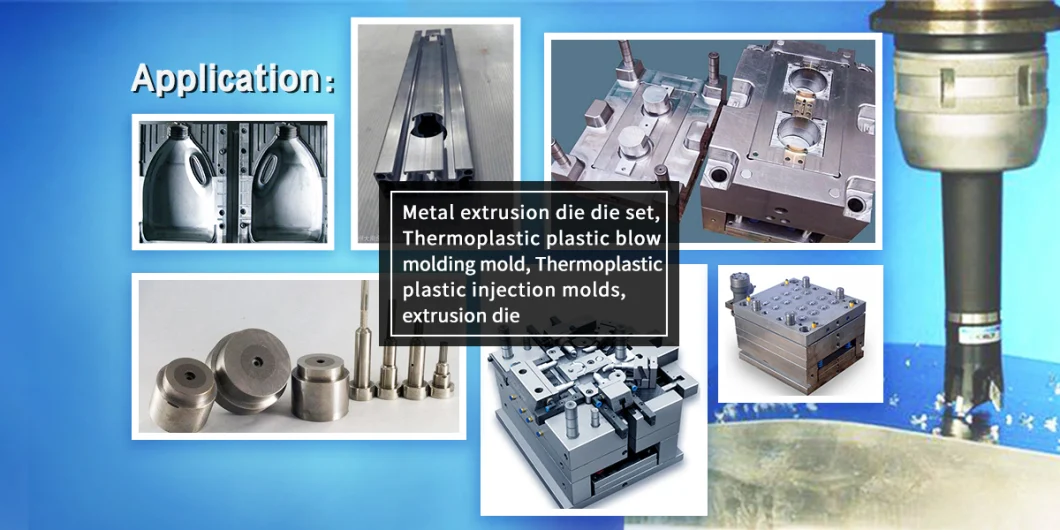

6.Application:

Used for various large-sized or medium-sized precision plastic mold and alloy parts.

Ideally suited for the production of plastic molds;

Die holders, zinc die casting dies, backers, bolsters and injection molds;

Shafts rail and wear strips;

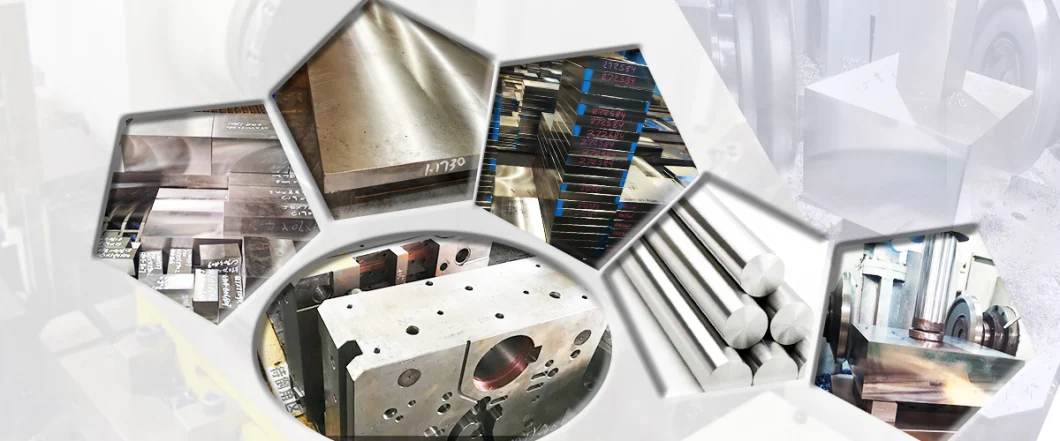

7. Stock:

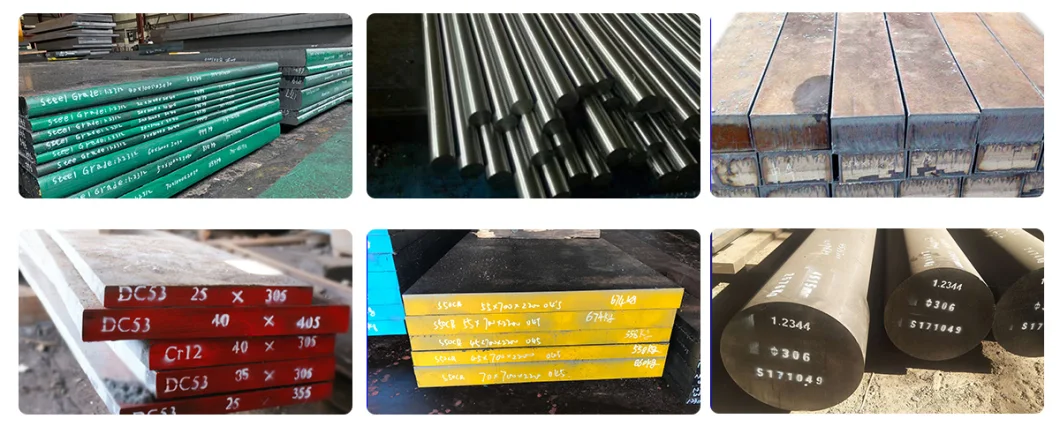

High-quality stock for various steel flat bar and round bar.

Alloy steel / Cold work steel / Hot work steel / Plastic mold steel and Stainless

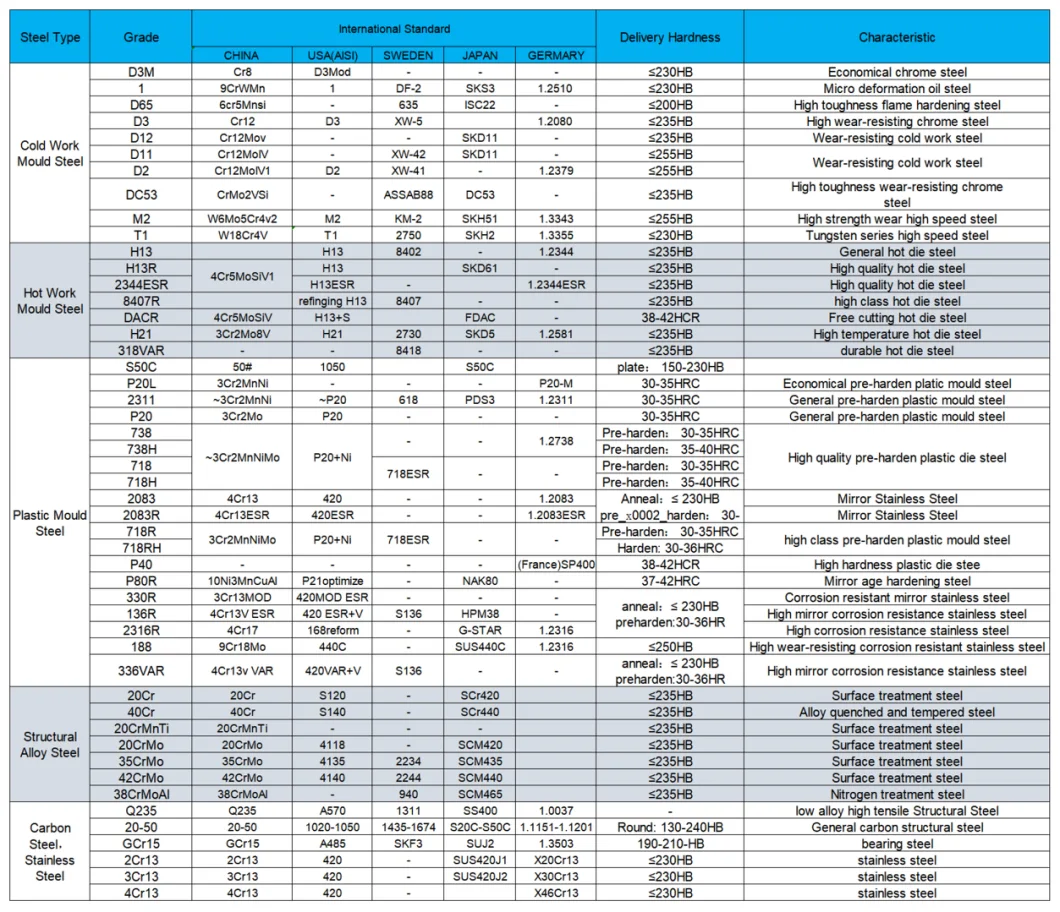

For more tool and die steel please check the list:

8. About us :

Hong Kong JIMI STEEL (XINGXIONG CO., Ltd) XINGXIONG Co., Ltd. Was established in 2012, located in the Shunde District of Guangdong Province, It is an import and export trading company mainly engaged in advanced special steel, die steel, alloy steel, and steel processing general machinery and equipment. The company adheres to the concept of "high quality, high requirements and good faith",

Cooperating with more than 20 famous steel mills in China, rich in spot stock of products.

Our company has a variety of processing equipment and all kinds of inspection and testing equipment, such as horizontal sawing machine, vertical sawing machine, milling machine, bilateral milling machine, precision milling machine, plane grinder and so on. The products with short producing time, excellent quality and high precision can provide a high-quality product choice for the vast number of customers at home and abroad.

Our customer group spread all over the domestic provinces and cities, abroad including Europe, the United States, Australia, the Middle East, Southeast Asia and other more than 20 countries and regions, along with over 100 long-term stable cooperation customers...Choosing Xingxiong will bring you a better experience.

PLASTIC MOULD STEEL: 1.2311, 1.2312, 1.2738, P20, 1.2083, 1.2316, NAK80, P40, 1.2738HH

HOT WORK MOULD STEEL: 1.2344, SKD61, H13, H11, FDAC, 8407

COLD WORL MOULD STEEL: SKD11, D3, SKS3, 1.2080, 1.2379, CR12MOV, O1, D2

STRUCTURAL ALLOY STEEL: 4140, 20CR, 40Cr, 35CrMo, 42CrMo, 38CrmoAi, SCM440, SCM420, 1.7225

CARBON STEEL &: Q235, Gcr15, S45C, S50C, S55C

CNC surface grinding machine, NC side boring machine, Band saw, CNC double head machine, Vertical Band saw, CNC milling machine, Double alloy saw blade, wireless remote control crane, Magnetic chuck

9.Our Service

UT TEST

For Guarantee Product Quality.

A. Sand Hold Detection;

B. Hardness Detection.

MACHINE MILLING SERVICE

For Customer a Various of Requirement

A. Steel plates: Cutting by bandsaw machine, milling, heat treatment, etc

B. Round bars: Cutting by bandsaw machine, peeling, grinding and turned, heat treatment, etc

Finish Product:

10.Delivery Time

1) For abundant stock, 7-15 days.

2) For customized products, 15-30 days.

Loading Details:

11.FAQ:

Q1: What do you do for the control of the quality?

A1: Before loading into the container, our products will all be inspected by ultrasonic inspection. Quality Grade conforms to SEP 1921-84 E/e, D/d, C/c as per customer's request.

Q2:: What are your hot-selling products?

A2: D2/1.2379, H13/1.2344, CR12MOV, DC53, CR8, abundant stock for both plates and rounds. Competitive prices and short lead-time.

Q3: Can we visit your company and factory?

A3: Yes, warmly welcome! We can book the hotel for you before you come to China and arrange our driver to our airport to pick you up when you come.

Q4: Are you a manufacturer or merely a trader?

A4: We are a group of companies and owned manufacturer bases and trading companies. We specialized in plastic mold steel, hot work mold steel, cold work mold steel, alloy steel for mechanical, high-speed steel, etc. All materials are of high quality and competitive price.

HOR SALE GRADE:

Plastic Mold steel: P20 / NAK80 / 2083R

Cold Work Steel: DC53 / Cr12 / M2 / T1

Hot Worl Steel: H13 / H13R / 1.2344

Alloy Steel: 20Cr / 4140 / SCM440

Carbon steel Stainless: GCr15 / 304 / SUJ420

↓For Details Please Contact Us↓